One of the major challenges facing companies that are responsible for managing the world’s infrastructure networks is data quality. I have blogged about data quality on multiple occasions (here, here, here and here). At Autodesk University Peter Barcza, Managing Director of BPMC Ltd., gave a fascinating presentation of how Hungarian State Railways (MAV), with a very tight budget and a legally binding deadline of January 2, 2011, which translated into a tight timeframe of a little over a year, was able to geolocate 1.35 million objects to 5 cm (2 inches) precision.

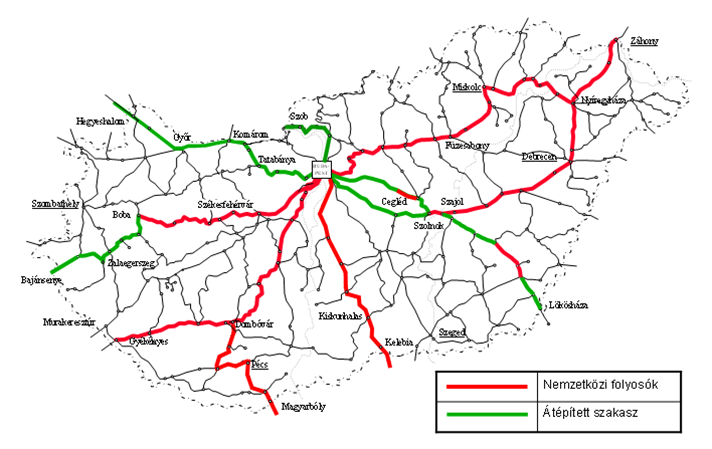

Data collection and data quality are the critical success factors for most GIS projects. From 50 to 90 percent of resources are often used for data collection and ensuring data quality. A railway is a multi-utility environment and the MAV team had to classify and geolocate 200 different types of equipment including 7800 km of track, bridges, signaling systems, energy supply, overhead power lines, telecommunications, real estate and facilities such as stations, and other non-MÁV objects. The original paper maps, some of which dating from the Austro-Hungarian Empire, were unreliable for a number of reasons and the precision was in the 1.5- to 2-meter range, inadequate for MAV’s purposes. Traditional surveying is time-consuming and MAV would have had to hire expensive external resources to conduct the surveying. To address these issues, Peter re-geolocated all of MAV’s facilities using an integrated GPS/GIS data collection process designed for a multi-utility environment.

Data collection and data quality are the critical success factors for most GIS projects. From 50 to 90 percent of resources are often used for data collection and ensuring data quality. A railway is a multi-utility environment and the MAV team had to classify and geolocate 200 different types of equipment including 7800 km of track, bridges, signaling systems, energy supply, overhead power lines, telecommunications, real estate and facilities such as stations, and other non-MÁV objects. The original paper maps, some of which dating from the Austro-Hungarian Empire, were unreliable for a number of reasons and the precision was in the 1.5- to 2-meter range, inadequate for MAV’s purposes. Traditional surveying is time-consuming and MAV would have had to hire expensive external resources to conduct the surveying. To address these issues, Peter re-geolocated all of MAV’s facilities using an integrated GPS/GIS data collection process designed for a multi-utility environment.

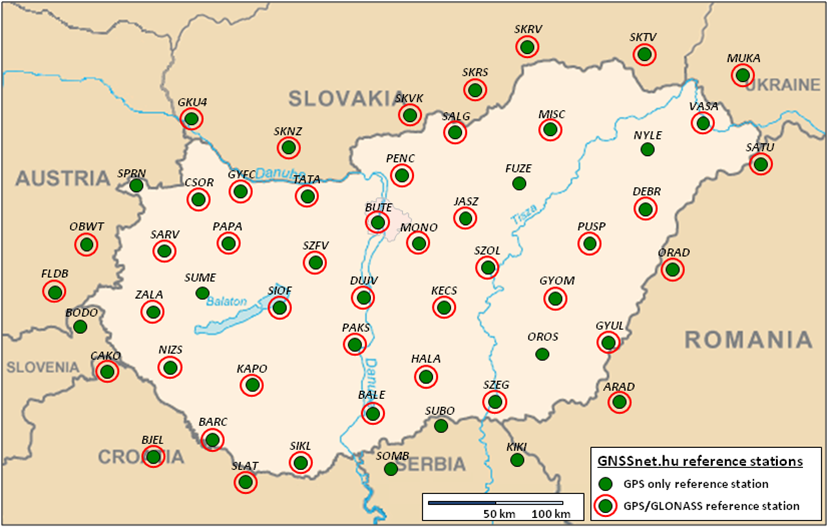

After analyzing various alternatives, the MAV team decided that given the tight budget and the tight timeframe, GPS/GLONASS based data collection was the only feasible strategy. A country wide GNSS RTK system of 54 earth stations (≤2 cm [1σ] horizontal, ≤3 cm [1σ] vertical) meant that the measurement precision was estimated to be within 5 cm (2 inches), which was adequate for MAV’s purposes. Data would have to be collected in the field for later processing because of the difficulty in geolocating and collecting attributes of many of the objects. The data collection process was designed to ensure efficient, semi-automatic, data upload to the GIS system. A reliable country wide GPRS communicatiions network made this approach feasible. The GIS system was comprised of an Oracle Spatial database, AutoCAD Map 3D Enterprise, and Autodesk Infrastructure Map Server.

After analyzing various alternatives, the MAV team decided that given the tight budget and the tight timeframe, GPS/GLONASS based data collection was the only feasible strategy. A country wide GNSS RTK system of 54 earth stations (≤2 cm [1σ] horizontal, ≤3 cm [1σ] vertical) meant that the measurement precision was estimated to be within 5 cm (2 inches), which was adequate for MAV’s purposes. Data would have to be collected in the field for later processing because of the difficulty in geolocating and collecting attributes of many of the objects. The data collection process was designed to ensure efficient, semi-automatic, data upload to the GIS system. A reliable country wide GPRS communicatiions network made this approach feasible. The GIS system was comprised of an Oracle Spatial database, AutoCAD Map 3D Enterprise, and Autodesk Infrastructure Map Server.

Quality systems

Quality systems

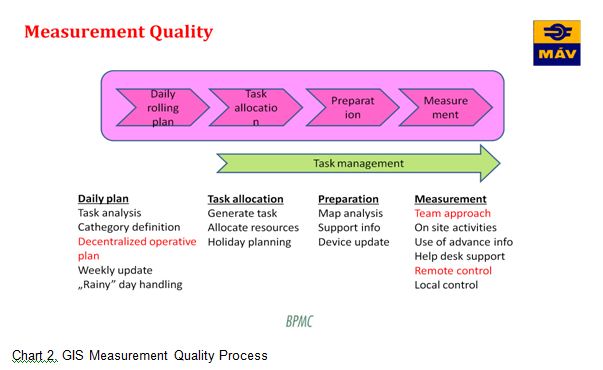

The key to the success of the project was the quality systems focussed on design, field data collection (“measurement”) and data upload. Multiple layers of control ensured that all data was reviewed, accepted or revised within eight days of collection. The first level of control was local teams from seven differenmt departments in six different territoreis reviewed collected data independently. The field data collector did not partcipate in this review. A second level of control reviewed data at a national level.

Results

Results

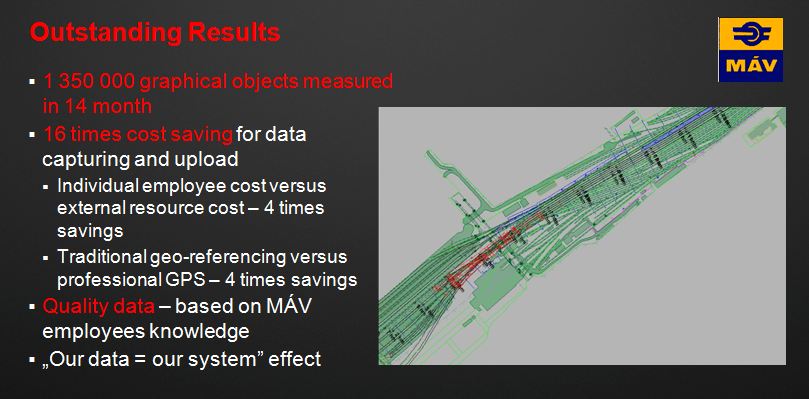

MAV was able to complete the survey of 1.35 million objects by January, 2011. In the process 20% of the assets were “discovered”, meaning that they were previously undocumented by MAV. The discovered objects included 500 properties (land parcels) that belonged to MAV but about which MAV had no records.

The work was done entirely by MAV employees which made it much less expensive than if external contractors would have had to have been used. Overall it is estimated that as a result of using internal resources and a GPS/GLONASS-based approach the project was 16 times more efficient than a traditional survey. And the project generated a lot of pride among MAV employees who carried out the work because it was such a remarkable achievement from a data collection, management and quality perspective.

Be the first to comment