Debra Brooks and Jennifer Ryan of Southern California Edison (SCE) gave an outstanding presentation at Autodesk University on SCE’s vision and approach in standardizing and unifying design processes for distribution and transmission.

SCE is one the largest U.S. electric utilities serving Los Angeles and other cities in a 50,000 square-mile service territory. It provides power to nearly 14 million people. SCE is in the forefront of major trends that are transforming the electric power grid worldwide. In 2010 19.4% of electricity demand was provided by renewable energy. As of right now about 3,500,000 smart meters have been installed at customer sites as part of SCE’s SmartConnect program.

SCE has about 700 distribution and transmission designers and is facing the same aging workforce challenges that other utilities are. In 2006 realizing that they needed to improve productiivity by bringing consistency and efficiency to distribution and transmission workflows, they began a business process transformation initiative.

Change management

Managing change is not easy in any organization and the larger the organization the harder it is. SCE has over 15,000 employees in distribution and transmission. One of the first things they did was remind themselves of their history to prepare for the coming change. SCE has been in existence for 125 years. About 1888 the population of Los Angeles reached 100,000 and shortly after that in 1894 the Los Angeles Edison Electric Company was created as an Edison franchise. I was surprised that SCE was the first utility to have an air polution control system, but this is LA. SCE generates most of its own power using hydroelectric, nuclear, solar, wind, and cogeneration facilities.

But they knew that they had to replace aging with new equipment, comply with increasing regulation, invest in new technologies and become more efficient often with a smaller workforce. SCE’s number one focus is safety, but they also had to address increasing customer expectations. They realized that they had to break out of their current siloed systems to integrate engineering design, ERP, dispatch, material ordering to name just a few of their enterprise systems. When they started this process their different transmission, distribution, substation design groups were using different technologies.

But they knew that they had to replace aging with new equipment, comply with increasing regulation, invest in new technologies and become more efficient often with a smaller workforce. SCE’s number one focus is safety, but they also had to address increasing customer expectations. They realized that they had to break out of their current siloed systems to integrate engineering design, ERP, dispatch, material ordering to name just a few of their enterprise systems. When they started this process their different transmission, distribution, substation design groups were using different technologies.

IPSEC

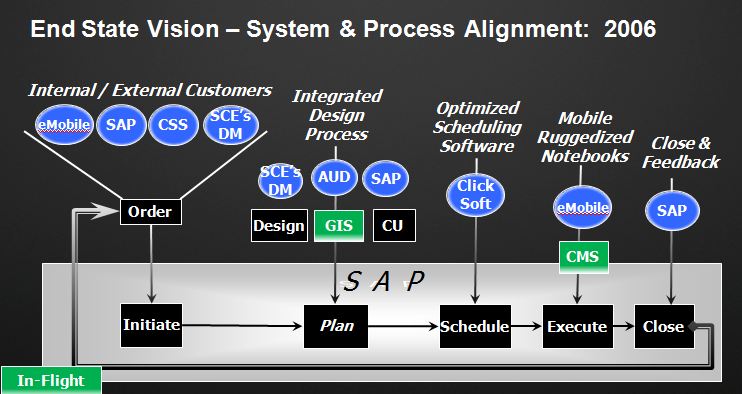

From the beginning the business process transformation relied on analyzing workflows using an IPSEC methodology. IPSEC stands for Initiate, Plan, Schedule, Execute, and Close. They also looked at alternative enterprise system architectures including relying on one vendor or an ERP plus bolt-ons approach and decided to adopt the latter.

Graphical design

Graphical design

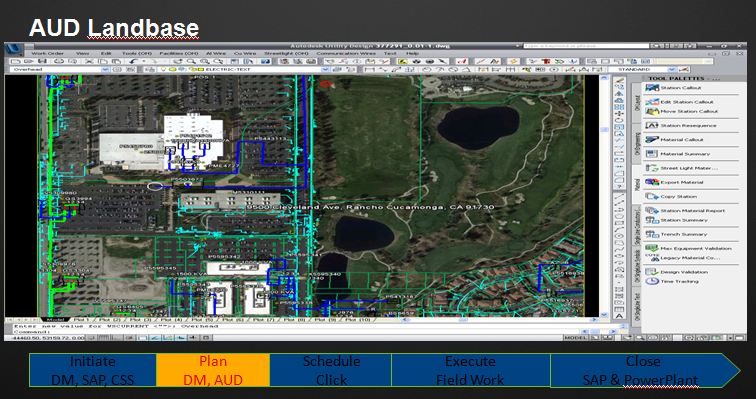

They started the graphical design project in 2007 using Autodesk Utility Design (AUD). In 2010 graphical design was integrated with SAP, in January 2009 the solution was deployed to distribution, and in November 2010 to transmission.

Compatible units

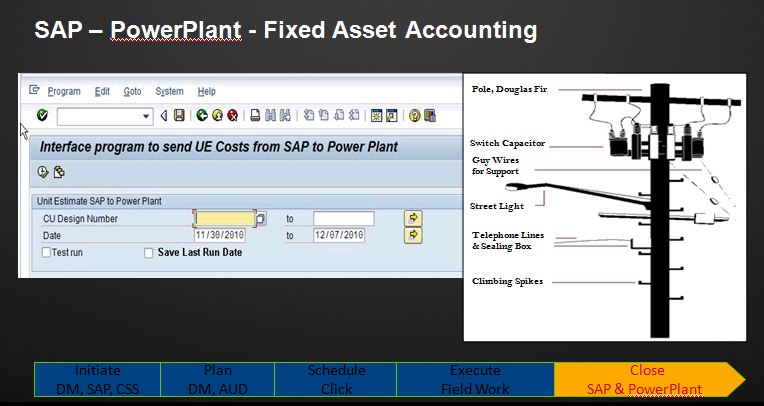

One of the workflows SCE focussed on was compatible units (CUs). CUs represent the cost of equipment together with the cost of labour to install the equipment. When combined with a bill of materials (BOM), CUs allow you to generate job estimates. The compatible uinit workflow involves many systems including design, crew scheduling, materials ordering, and fixed asset accounting.  In the context of an IPSEC workflow, the enterprise systems involved include

In the context of an IPSEC workflow, the enterprise systems involved include

- Initiate – Design Manager, ERP (SAP), Customer Service System

- Plan – Design Manager, Graphical Design (AUD)

- Schedule – Crew scheduling (Clicksoft)

- Execute – Field operations (eMobile)

- Close – Finance (SAP and PowerPlant)

One of the big benefits on an integrated approach is that it eliminates a lot of redundant data entry. As Jennefer explained, when she was a designer she had to manually list the bill of materials on the design drawing and repeat it, again manually, in the materials ordering system.

One of the big benefits on an integrated approach is that it eliminates a lot of redundant data entry. As Jennefer explained, when she was a designer she had to manually list the bill of materials on the design drawing and repeat it, again manually, in the materials ordering system.

Lessons learned

Debra summarized SCE’s experience in transforming their business processes especially engineering design. The things that worked well for them were

- Phased implementation of technology to minimize impact on the users

- Including testing, especially perfromance testing, as part of the project scope

- Getting and retaining stakeholder engagement from the beginning and through the duration of the project

The areas where they felt they could do better were

- Managing utilitzation expectations

- Scope creep for graphical design

- Managing project scope in the context of available resources (people)

- Making sure that the system test environment was a true replica of the production environment

All in all this represents a remarkable business process reengineering achievement, especially for a company the size of SCE.

Be the first to comment