There are over 12 000 substations in the US and over 1 300 in Canada and the average age of the transformers in these substations is over 40 years old. As a result of the green energy/smart grid impetus, many people expect that all of these substations are going to be rehabilitated, retrofitted, or replaced over the next decade. The $3.4 billion worth of grants recently awarded to 100 companies across the US by the Department of Energy includes funding for retrofitting 700 substations.

The electric power industry is also faced with an aging workforce, so design productivity is a top priority.

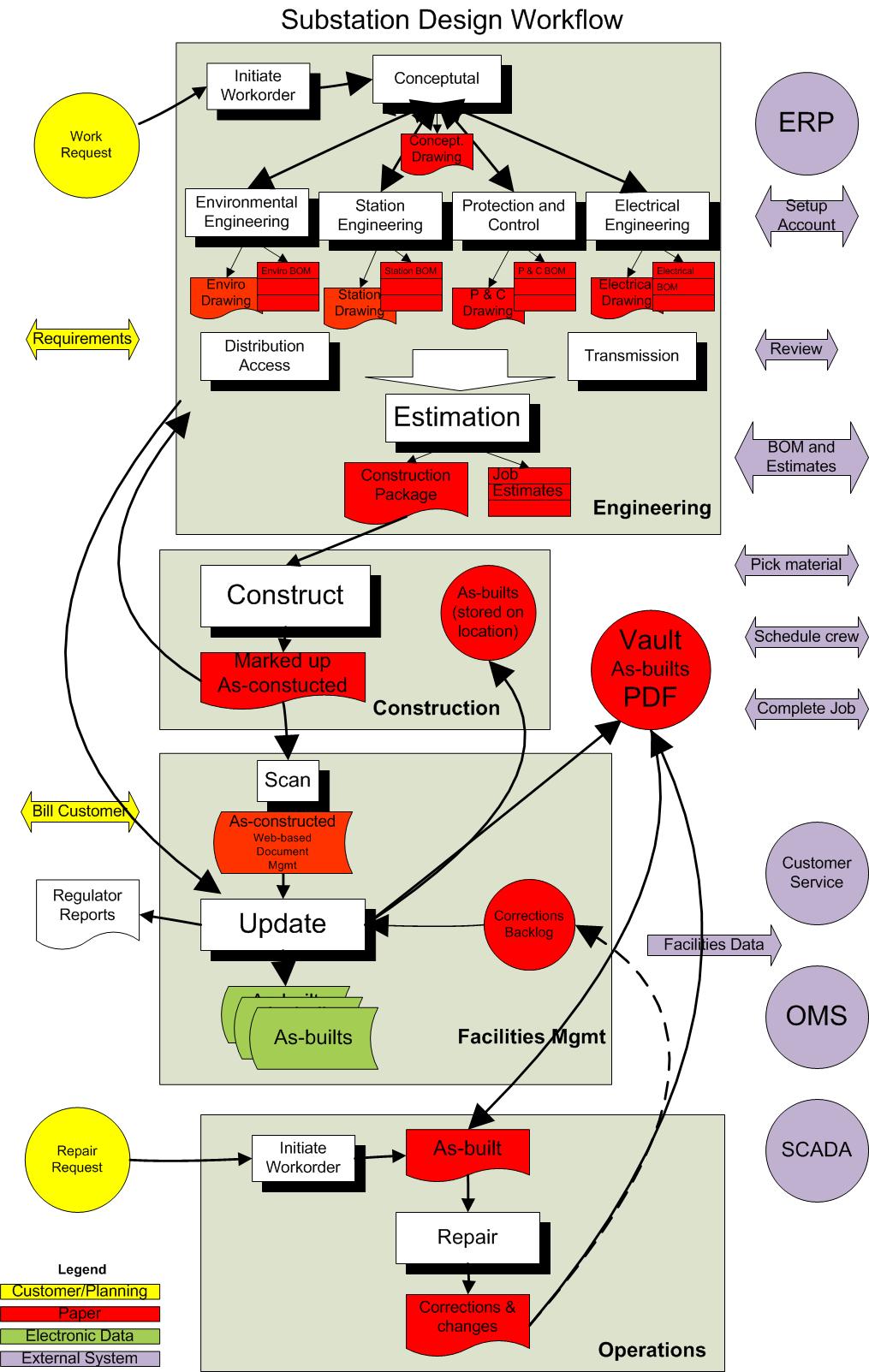

Substation Design Workflow

Designing a substation involves a quite complicated design process requiring the collaboration of different disciplines such as electrical engineers, protection and control engineers, civil engineers, environmental engineers, and often transmission engineers. The workflow typically begins with a concept drawing, which is used by the different teams to prepare detailed engineering drawings of the electrical, protection and control, physical and environmental aspects of the structure.

Designing a substation involves a quite complicated design process requiring the collaboration of different disciplines such as electrical engineers, protection and control engineers, civil engineers, environmental engineers, and often transmission engineers. The workflow typically begins with a concept drawing, which is used by the different teams to prepare detailed engineering drawings of the electrical, protection and control, physical and environmental aspects of the structure.

From the detailed drawings, a bill of materials (BOM) is compiled which is used to prepare job estimates. This is a critical and time consuming part of the design effort, because the engineers in all disciplines need to avoid underengineering, which can result in outages, and overengineering, which is expensive.

After project approval, the engineering drawings are provided to the construction contractors who build the substation. Upon completion of the construction phase, the as-builts are returned to the records group.

As-builts are stored in a vault, or secure location, as well as at the substation itself to be used by repair crews when there is a malfunction.

There is a very worthwhile article recently published in Electric Energy T & D Magazine where Arnold Fry, Supervisor for Substation Engineering Services at Duke Energy, outlines the substation design process in detail.

One thing that is immediately noticeable about the substation design process is that there is a lot of paper, which is symptomatic of manual workflows. For example, at Duke Energy preparing the BOM is a manual process that can take as much as 40 of the total 200 hours required to compete a substation design.

Automating Substation Design

Electric power companies are looking at ways to automate the design process. At Duke Energy they have developed the Duke Energy Substation Design Solution (SFS) which automates the design of electrical control systems, uses model-based design for the structural design, manages a library of reusable components, automates the creation of the BOM, and helps the different disciplines to collaborate in developing the final design through 3D visualization, which enables the engineers to see how the different components fit together.

Duke Energy estimates that SDS will reduce design time by at least 50% for both greenfield and brownfield projects. The Duke Energy SDS will be coming on line just at the time when the company is accelerating its smart grid deployment and will enable it to pursue an ambitious substation retrofit program.

Be the first to comment