One of the things that has struck me after a number of years travelling and visiting utilities and telecoms world wide is the similarity of the process used to design and manage utility and telecommunications networks, not only across different geographies but across different sectors, power, water, waste water, gas, cable, and telecom.

The basic process for designing and managing a network is essentially the same the world over.

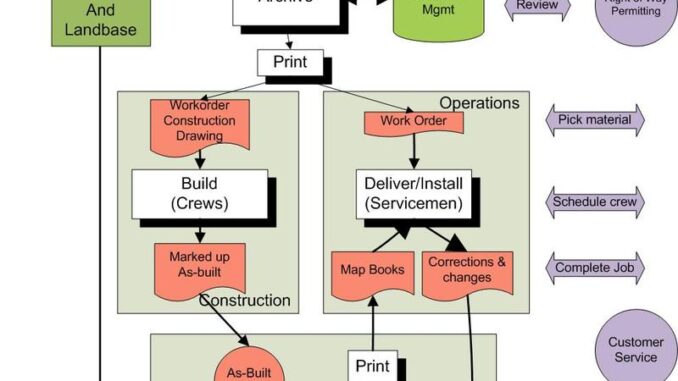

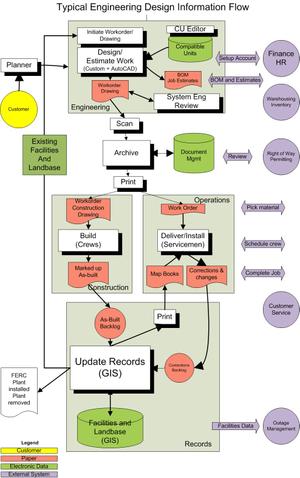

Engineering Design

Designers or planners create the initial design, called a construction drawing, for the facilities to be constructed. Designers need to worry about three things; physical things like attenuation or voltage drop, sag between poles for aerial facilities, pulling tension for underground facilities, gravity and flow direction for waste water; financial things like bill of materials and job estimates; and adhering to the engineering design standards of the organization. These are important because they not only ensure that facilities are depicted in a way that everyone understands, but also that the data model which defines types of equipment like transformers, conductors, and fuses, properties of each type of equipment like voltage, year installed, and manufacturer, and relationships between different types of equipment, such as connectivity is enforced. Enforcing the data model is critical because it enables functionality like finding customers affected by a failed transformer or a controlling device that has left customers without power. In many organizations engineering design standards are enforced by either an in-house developed custom application or, as is often the case if the design work is outsourced to contractors, by an in-house developed custom QC (quality control) application that is used to verify that drawings submitted by contractors meet the organization’s standards.

Construction

Construction crews, often comprised of sub-contractors, build the facilities using paper construction drawing. During construction, the drawing may be marked up or redlined to reflect changes in the original design. After construction is completed, the construction drawing, now referred to as an “as-built”, is forwarded to the records department.

Records or Network Documentation

The records department enters the as-built into the permanent records database, which is maintained as the company’s record of its network infrastructure. The records database is used for a variety of activities such as reports about the network requested by the regulator or my management. For work relating to connecting or disconnecting customers to the network, adding new services, repairing or replacing network facilities, the records department is responsible for preparing facilities maps to assist field staff.

Operations

Operations field staff are responsible for fulfilling work orders responding to customer requests, outage events, and maintenance. Work orders typically involve installation of new facilities or repair of existing facilities. Field staff use facilities maps in finding and identifying network facilities such as transformers and fuses in a power grid, valves in a gas or water network, amplifiers and nodes in a cable network, or pedestals and cross-connects in a communications network. Ideally the facilities maps are returned to records with markups that show corrections and changes to facilities data reported by field staff.

Utilities and telecommunications companies are facing the same global challenges that other sectors such as construction are, global climate change which is forcing utilities to reduce carbon emissions, aging infrastructure, and an aging and shrinking workforce which is motivating efforts to improve productivity. One way of improving the productivity is to improve the flow of engineering design information through engineering design, construction, and operations lifecycle and to achieve this utilities and telecommunications companies are focusing on seven areas where they see that often significant improvements in productivity can be made.

1. Improving Design Productivity

Design productivity has become critical as a result of the aging and shrinking workforce which means that organizations need to do more with less. Organizations are losing experienced designers to retirement faster than they can replace them with younger inexperienced workers. This means that they are not only facing reduced headcount, but also fewer experienced workers.

Organizations are looking to improve productivity by speeding up the design process by 1) integrating engineering calculations such as attenuation, voltage drop, guying, and pulling tension and 2) automating bill of materials and job estimation, and 3) ensuring that networks are built to engineering standards to avoid costly failures. In addition organizations are looking to reduce costs by optimizing the network by avoiding over-engineering by ensuring that equipment is sized appropriately for the requirements.

2. Eliminating In-house Developed Custom Code

IT departments in utilities and telecoms have realized that maintaining in-house developed custom code is expensive and are looking for COTS (commercial off the shelf) applications to replace their in-house developed code.

3. Improving Flow of Design Information Between Field Staff and Records

The field staff are often frustrated by the poor quality of the facilities maps they receive with their work orders. They are also frustrated by business processes that more often than not discourage field workers from providing

valuable information back to records about inaccuracies they observe in the field or about changes they have made. Organizations are looking to implement mobile solutions that enable field workers to not only have immediate access to the records database, but increasingly enable field workers to provide valuable updates from the field to records. Field workers are familiar with facilities because work with them daily, and they need accurate data about facilities to be productive. By enabling field workers to participate in maintaining records data, data quality can be improved which enables field workers to be more productive.

4. Resolving the As-built Problem

One of the major challenges in utilities and telecoms face is the “as-built” problem. A symptom of this problem that can be found in utilities and telecoms is an as-built backlog, comprised of as-builts returned from construction that are waiting to be entered into the records database. These backlogs, which can stretch from several months to years, mean that the records database is always out-of-date making it difficult to provide reliable information about network facilities to the field, management, and the regulator.

5. Eliminating redundant data

Another problem associated with the as-built problem is data redundancy. In many organizations the as-built problem is the direct

result of paper flow, paper as-builts coming back from construction are

redigitized into the records database, often a traditional GIS. Organizations are looking to find ways of eliminating as-built backlogs and the data redundancy resulting from a paper-based information flow.

6. Improving the Quality of the Facilities Database

Poor data quality has serious implications for the organization such as unreliable reports prepared for management and for regulators, which can lead to massive fines such as though seen in the water industry in the UK, negative impacts on the productivity of field staff with the concomitant impact on the bottom line, lengthening the time required to respond to outages, and inhibiting the rapid deployment of new services because the design data critical for servicability calculations used to customer access to services such as broadband, cable, or power is either not available or unreliable. Estimates of the quality of records databases in many utilities and telecoms in North America are on the order of 70% or poorer. Some telecos, for example, have found that the quality of their databases are so poor that they have sent crews to the field to recapture the facilities data that is critical for determining broadband serviceability.

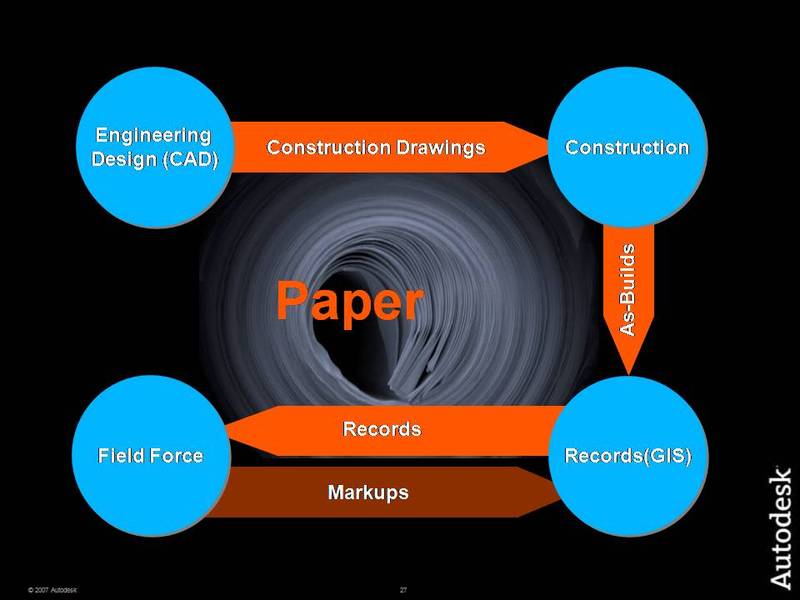

7. Reducing Paper Flow

One of the things that leap out of diagrams of the flow of engineering design data in utilities and

telecoms like the one I have included is the problem of islands of technology (CAD, GIS, …) connected by paper-based information flows. If you look at the diagram of the flow of engineering data in a utilities or telco that I have included, you can see a lot of paper flows, represented in the diagram by red. For example, in many organizations the as-built problem is the direct result of paper flow, paper as-builts coming back from construction are redigitized into the records database. Organizations in all sectors are looking to reduce the flow of paper, not only as part of a green initiative to save trees, but also because paper flows result in data and process redundancy, inhibit productivity, and impair the agility of the organization. Organizations have looked at what has happened in the banking industry, airline industry, and web-based retail, and can see the benefits of reducing paper-based information flows.

‘

Be the first to comment