At the National Rural Electric Coop Assn (NRECA) TechAdvantage Conference in Nashville, Nathan Frisby, GIS Engineer at Big Sandy Rural Electric Coop (RECC), and David Herron of Leidos gave a presentation about their experience implementing a GIS at Big Sandy.that I think would be of interest to any utility that has data quality issues, in other words, most utilities. Their experience was particularly notable because Big Sandy is a very small utility with about 13,200 customers and commensurately limited IT resources, but they managed to get the data quality part right. I’ve blogged on many occasions about the challenge of data quality of location information at utilities. It is a major challenge, and one that the move to smart grid is forcing all utilities to address. Big Sandy focused not only on ensuring that the location and other data they captured was accurate and up to date, but they implemented business practices to ensure that the high level of data quality is maintained.

Big Sandy RECC provides electric power services for 13,200 members in an 8 county territory in Kentucky that is too rural to be of interest to the investor owned utilities. The people in the area got together and formed a coop in 1940.

Collecting location data

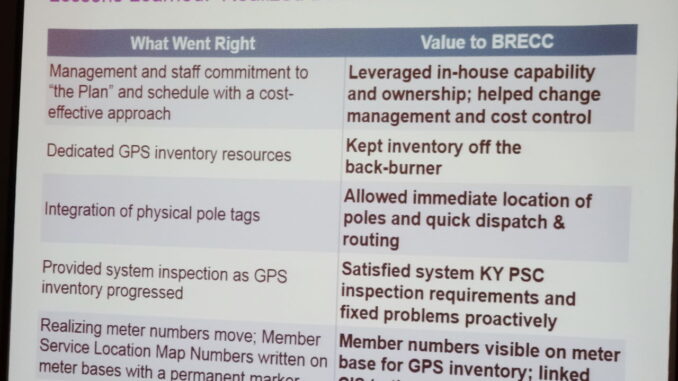

The first step in the process they went through was a GPS inventory of everything in the field including meters, poles, transformers, lights, fuses, and so on. As part of this effort they physically tagged all their poles with a unique serial number. When they inventoried poles they captured everything on them including transformers, conductors, insulators, cross arms and equipment from other utilities such as the local phone company (joint use). But they went one step further and noted any problems such as broken cross arms, cracked insulators, or rotten poles. This amounted to a full inventory plus a full field inspection. One of the reasons this was so successful is that the folks that conducted the inventory were a dedicated team whose sole responsibility was the GPS inventory.

Another thing they did at the same time that was also critical to down the road was linking customers addresses to meters and meters to transformers. As I have blogged about, linking customers’ addresses to meters is a challenge for many utilities, but it is essential for many critical applications including outage management.

Maintaining data quality

Their data quality maintenance program is basically a double check system. The field worker, typically a linesman, records the changes he/she makes on the work order which is returned to the records team. In addition once a month, a supervisor takes all the completed work orders and goes out in the field and verifies the changes recorded on the work order, looking carefully for any deviations between what he finds in the field and what is recorded on the work order. Only after that is the asset database updated.

Benefits

Some of the significant benefits that Big Sandy has realized by implementing a GIS with ensured location data quality include,

- Greater resilience – outages are fewer and of shorter duration because reliable location data fro their assets means they can respond faster. Linesmen non only know exactly where a downed pole is, but also exactly what equipment is on the pole. Nathan Frisby said he was uncertain whether he would be able to attend the NRECA conference to give his talk because they experienced an ice storm in the beginning of the week. But he said that their distribution system is so much more reliable now that he was able to make it to the conference.

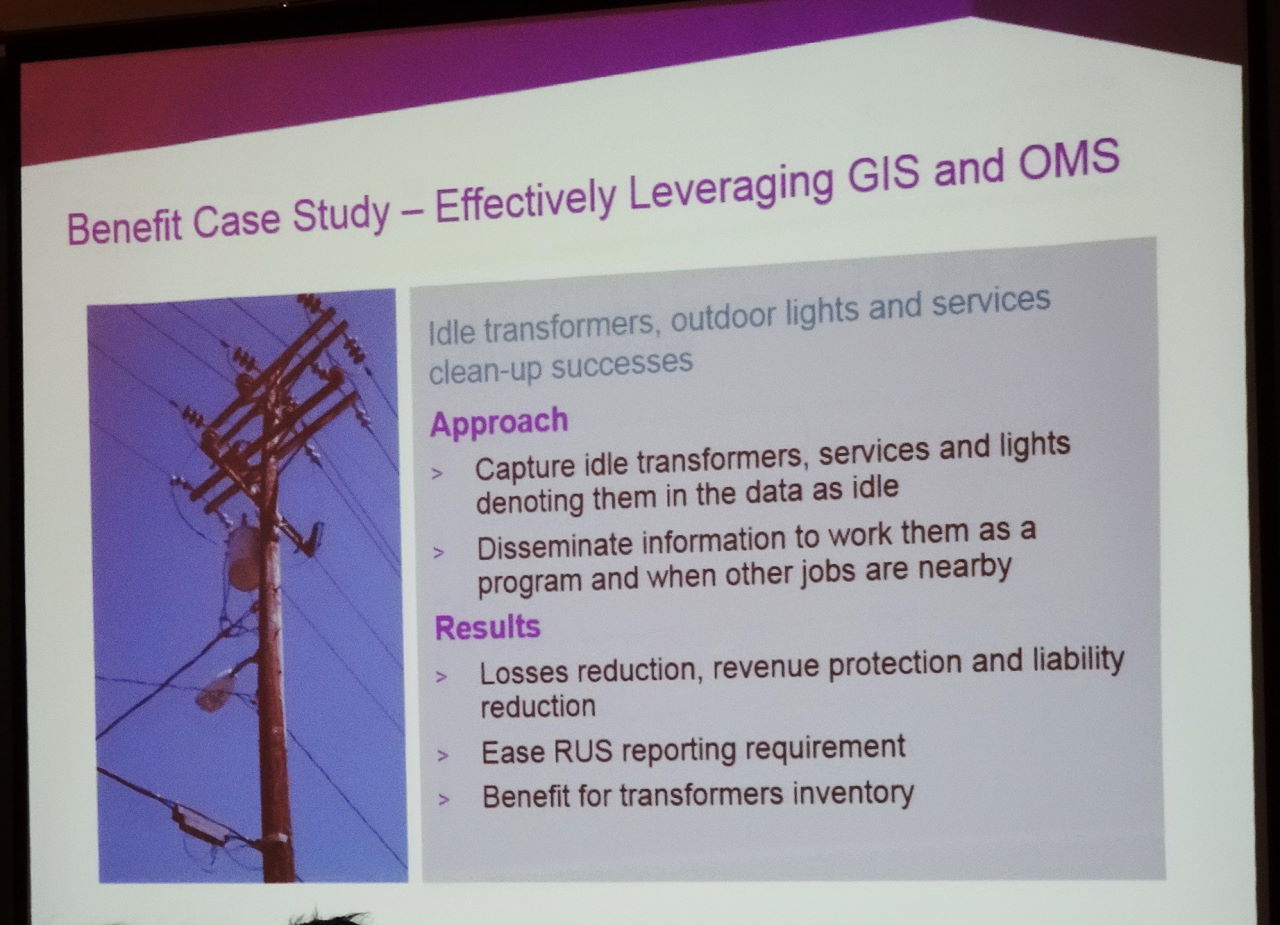

- Reliable reporting to RUS and FEMA – They found idle transformers, power lines that were not on any paper maps, and duplicate transformer numbers. For 1500 transformers the data currently in the database was incorrect and had to be corrected.

- Improved disaster response – When they have a storm and get assistance from nearby power utilities, they are able to provide reliable maps to direct the folks from other utilities who are not familiar with the service territory to poles and other assets that need servicing.

- Fewer truck rolls to respond to 811 One Call Center – They were able to reduce the number of truck rolls because they know precisely where all their assets was and often did not have to roll a truck.

Perhaps the most telling benefit is how it has improved their ability to report after a disaster to FEMA. For example, after an ice storm in 2012 that fortuitously had hit an area they had GPS inventoried some time prior to the storm, it helped them report accurately their claims for damages to FEMA. When the FEMA inspector visited them to verify their claims, she randomly selected 12 poles and then asked to go out in the field to visit those 12 poles to verify that what was recorded on the work orders corresponded to the work that had actually been done on the assets. After visiting three poles and comparing the very detailed information that Big Sandy had recorded, she was so impressed with the accuracy and detail, she said that this was the most detailed and reliable data she had seen and she didn’t need to visit any more poles. Very impressive!

Perhaps the most telling benefit is how it has improved their ability to report after a disaster to FEMA. For example, after an ice storm in 2012 that fortuitously had hit an area they had GPS inventoried some time prior to the storm, it helped them report accurately their claims for damages to FEMA. When the FEMA inspector visited them to verify their claims, she randomly selected 12 poles and then asked to go out in the field to visit those 12 poles to verify that what was recorded on the work orders corresponded to the work that had actually been done on the assets. After visiting three poles and comparing the very detailed information that Big Sandy had recorded, she was so impressed with the accuracy and detail, she said that this was the most detailed and reliable data she had seen and she didn’t need to visit any more poles. Very impressive!

I would also add that the high quality of their spatial data means they are well prepared for smart grid.

Be the first to comment