WNN has outlined the sequence of events at Fukushima Daiichi.

Only three reactors, Units 1, 2 and 3, all boiling water reactors, were in operation at TEPCO’s Fukushima Daiichi nuclear power plant when the biggest earthquake that has ever been recorded in Japan happened. All three operating units underwent automatic shutdown as designed. Shutdown means that control rods, which absorb neutrons and stop the uranium chain reaction, were inserted into the reactor cores. At most if not all nuclear power plants, in an extreme emergency this will happen automatically without human intervention. And in all modern plants, it will happen even if all electric power fails.

Immediately as a result of the earthquake off-site power failed . (One of the things I realized when I visited Temelin Nuclear Power Plant, is that the power the plant itself uses comes from an external site not from its own generators.) As they are designed to do, as soon as off-site power failed, diesel backup generators started automatically and began to supply power to replace the failed off-site power.

But all Japanese nuclear plants are on the coast, to take advantage of ocean water for cooling. Daiichi was designed to withstand a tsunami, but only up to 6.5 meters high. In this case, because of the magnitude and proximity of the earthquake, the tsunami that hit the plant was at least 7 meters in height. I heard reports of 10 meter high waves hitting northeast Japan.

When the tsunami hit, the backup generators stopped, and the plant was left with no power. With no power, pumps stopped and the cooling systems were not able to remove the heat still being produced by non-uranium fission reactions. With no cooling, temperatures in the reactors rose, water levels dropped as the coolant evaporated, and pressures rose.

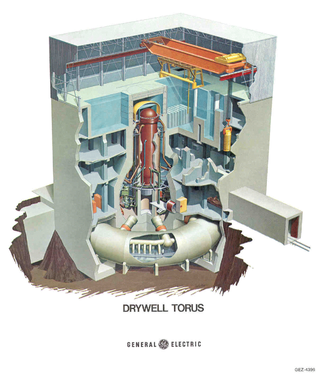

TEPCO brought in and installed mobile generators and managed to stabilize conditions at Unit 2 and to a lesser extent Unit 3. But there was not enough power to provide sufficient coolant to Unit 1. When the pressure becomes too high for the integrity of the containment vessel, it is necessary to vent steam, which is what TEPCO did. But when the water level drops below the top of the fuel rods, there is the risk of Cesium, Iodine, and H2 and O2, getting into the vapor, and when it is vented, the atmosphere. When TEPCO vented steam, they vented it into the concrete structure covering the containment vessel. The build-up of hydrogen and oxygen there resulted in an explosion that blew out the cladding, but left the steel structure and, most critically, the containment vessel intact. The venting also released a small amount of Cesium and Iodine. At this point, the government ordered the situation to be brought under control by the injection of seawater into the reactor vessel. From what I have read, seawater injection into the reactors has probably rendered them unusable. It may be some consolation to TEPCO that Units 1,2, and 3 are some of the oldest reactors in Japan.

Be the first to comment