At the SPAR International Conference in Colorado Springs this morning Magnus Rönnäng, Technical Expert in Virtual Manufacturing at Volvo Car Group gave a fascinating presentation on how Volvo has transformed the modeling of their automobile assembly plant using laser scanning.

Volvo is different from many other car manufacturers in having a single assembly line that is driven by customer orders (just-in-time manufacturing). Volvo makes 10 models and at any given time several of these models will be moving down the line.

When they introduce a new model, they can’t afford to shut down the assembly line. What they do is simulate in 3D how the new model will progress down the line. Until several years ago they simulated the assembly line using 3D CAD, but just the assembly line not the rest of the plant. That led to problems because they couldn’t determine from the simulation whether there was enough room outside of the assembly line to manipulate a new part or assembly. To resolve these issues they needed a model of the entire plant.

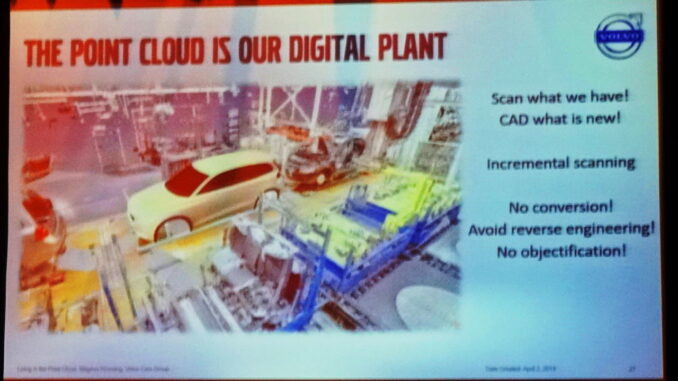

In 1999 they tried to model the entire plant using 3D CAD. By the time they completed the model, the plant had changed so much that the model was out of date. They tried to do this several times again with the same result. Then they decided to try laser scanning which turned out to be the solution. They laser scanned the entire plant. It took 2500 scans and generated 80 billion points. But they didn’t convert or reverse engineer the point cloud – the point cloud was the digital model of the plant. They abandoned trying to use 3D CAD for modeling the plant, and continued to use it only for the vehicles themselves and other movable and moving equipment.

The key to keeping the model up to date in a very dynamic plant environment is incremental scanning which allowed them to update only part of the point cloud model of the plant. This technique allowed them to scan new equipment installations and renovations and replace only part of the point cloud model.

Volvo uses commercial software that allows them to simulate a vehicle represented by a 3D CAD model moving through the point cloud of the assembly line and the plant looking for any collisions, basically a dynamic clash detection algorithm. They also use 3D visualization software to demonstrate to non-technical staff in management and on the Board of Directors how a new model moves through the assembly line.

Volvo uses commercial software that allows them to simulate a vehicle represented by a 3D CAD model moving through the point cloud of the assembly line and the plant looking for any collisions, basically a dynamic clash detection algorithm. They also use 3D visualization software to demonstrate to non-technical staff in management and on the Board of Directors how a new model moves through the assembly line.

Be the first to comment