What sets the new AEON humanoid robot apart from the pack, is that it is from a company that develops precision measurement solutions—a name very familiar to the surveying and geomatics sector

Mention bots, and the immediate reactions range from: “They’ll make our jobs easier and safer”, to “They’ll take or jobs!”, to “They’ll turn on us!”, etc. The reality of inevitable bot presence in our lives, and in surveying and geomatics, is much more complex than any single vision. The impacts (and benefits) will be felt by the industrial sector long before we see bots in our survey crews. However, current trends in instrumentation, and developments in the bot space, point unmistakably to such a future.

It has been a quarter of a century since Honda launched the pioneering humanoid robot Asimo. Since, we regularly see announcements of this-or-that-bot, usually shown dancing or some other demonstration of locomotion and agility. Recently, one news-magnet firm announced their own bot, which some fans, oddly, seem to think of as being the first humanoid bot. Whatever… Meanwhile, some of most meaningful R&D has continued without fanfare.

We’ve witnessed the success of Boston Dynamics SPOT, and its many applications. This has even been productized for reality capture. For instance, carrying the Leica Geosystems BLK ARC, and/or other sensors. Such early adoptions of semi-autonomous bots demonstrate realized value, but in some ways this is only setting the stage for what is to come.

Why Humanoid Bots?

Static, task-centric non-humanoid bots have been essential to the industrial sector for over half a century. If a task can be automated, someone will figure out how to do it. For certain types of tasks that cannot easily be automated, humans are still the best choice to provide the dexterity, autonomy, and versatility to tackle multiple, and varied tasks. There re now “cobots” that work in tadem to a human. Robotics is booming in the contruction sector, with automation and robotiocs dominating the International Construction and Surveying Exhibition (CSPI) ehibition held in Japan this month. Setting aside the subject of thought-work and AI, there are also physical tasks that humans are uniquely suited for. However, if a humanoid bot is developed to be highly capable in three keys areas—locomotion, manipulation, and inspection—it could perform a substantial array of tasks, rapidly, tirelessly and with less errors.

Let’s confront one of the biggest concerns folks have about bot workers; that they’ll take our jobs. In reality, even after a centuries of various kinds of automation, there are more people employed than ever before. As the population of many industrialized nations is levelling off, longer lives and prosperity has resulted in labor shortages in key age cohorts; more people in retirement and less entering the job market. Bots could solve some of this. For example, the greying of Japan has prompted integration of bots into various aspects of daily life; hospitality, factories, agriculture, elder care, entertainment, and more.

Bots in the workplace would increase productivity, and safety. Despite substantial up-front investment required, integrating bots is attractive, if not imperative, for industrial applications. The state of purpose-built, task-cnetric bots is highly refined, but limited to specific work. Humanoid bots are envisioned as filling the gaps where such solutions fall short.

Autonomy

AI is promoted as the key to autonomy for such applications. This is very true, but often the hype cycle of news about bots misses several other essential elements, without which such bots would not be possible or as effective and versatile as envisioned. Chief among these essential elements is precision measurement.

“I believe that the future won’t wait. It belongs to those who can measure accurately, act precisely, and unlock true autonomy”, said Burkhard Boekem, CTO of Hexagon in his Tech keynote at the HxGN LIVE conference, June 17th, 2025. Familiar brands under the Hexagon umbrella are focused on positioning, precise measurement and autonomy. These include Leica Geosystems, NovAtel, Septentrio, and more. Hexagon was founded, initiaslly as an industrial measurement firm. While it has expanded into many other fields, at the core, precision measurement reigns. Industrial metrology applications for manufacturing have increasingly adopted automation. For example, industrial trackers; handheld devices capable of measuring microns (for manufacturing applications). Surveying, geomatics, construction, and reality capture applications have also evolved to integrate automation at various levels.

A humanoid would not only need to rapidly and precisely capture its surroundings for locomotion, but apply even higher precision for actuation of say, hands and fingers. It is no surprise that a company with these overlapping areas of focus and expertise would embark on development of one of the most complex platforms for precise and dynamic measurement: humanoid bots.

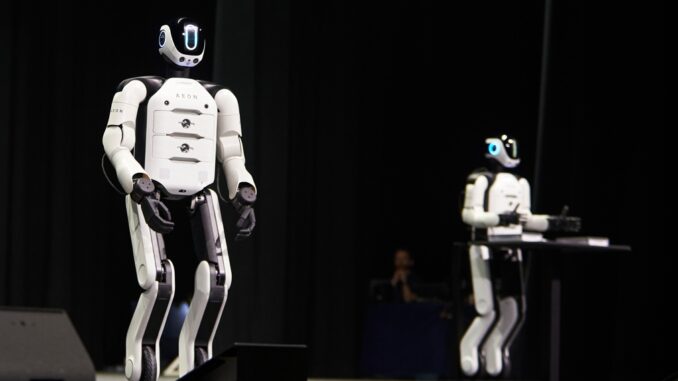

AEON

Introduced during the keynote address by Hexagon board chair Ola Rollén at the HxGN LIVE conference, the AEON humanoid for industry rolled onto the stage and introduced itself. No, it didn’t dance. I don’t care if a robot can dance, but can it do multiple useful tasks? Yes it can.

In a subsequent presentation, Arnaud Robert, CEO of Hexagon Robotics, provided more details about AEON, and had it perform live demonstration tasks. One was sorting parts, using both hands simultaneously. The other was using a handheld tracker (industrial metrology sensor), to inspect a car door. Ok, these might sound like things you would expect from a robot, but there’s a bit more going on…

Another key distinction between this and some other humanoids is that many tasks can be taught through “imitation learning”. As it shares a similar form factor, and moving parts, as its human teacher, the gestures and movements you demonstrate as you do a task, can be easily repeated by the bot.

Powerful AI in the AEON (huge processing stacks onboard) drive many other navigation, operation, training, and performance applications. For this, Hexagon partnered with NVIDIA. From a recent press release:

“To build AEON, Hexagon used NVIDIA’s three computers for developing and deploying physical AI systems. They include AI supercomputers to train and fine-tune powerful foundation models; the NVIDIA Omniverse platform, running on NVIDIA OVX servers, for testing and optimizing these models in simulation environments using real and physically based synthetic data; and NVIDIA IGX Thor robotic computers to run the models.”

No oThere are 22 sensors in the head of the AEON: inertial, cameras, and more. Photo: SchrockOne interesting example of what AI enhances for robotics is a “reward” approach to training and performance monitoring. It is not what you might think; in robotics, “reward” is not some form of emotive function, nor implying any level of sentience. In its simplest form, a reward could be characterized as sort of points system, tallying positive points for completed tasks, and negative for say, hitting obstacles. The tally serves as a metric to help better train the bot and improve operations. Of course, the design of an effective rewards system for bots needs to avoid some of the pitfalls of early systems, where bots might be compelled to complete short-term tasks rapidly, overlooking long-term goals. Such systems have come a long way, and the AEON benefits from the latest innovations.

Mechanisms for doing physical tasks have also come a long way, and AEON takes advantage of this. No more claws… The “hands” are capable of mimicking human hand movements to be able to pick up small objects. The array of actuators in the AEON in its appendages deliver 7 (or more) degrees of movement freedom. One of the first things that folks commented on was wheels instead of feet. For industrial applications, say a factory floor, wheels are the most efficient choice, particularly for turning and smoothness of movement. It can also climb stairs and step over obstacles without losing balance. I was told, off the record, that of course, if there was to be a field version someday, the feet could be different.

Reality capture is essential for human as well as humanoids. For a humanoid, it may not necessarily be for capturing 3D models or point clouds for engineering and mapping (yet). But, just like for humans, it is essential to navigate our world and as a reference for physical movements and tasks. It is not a surprise that many of the surveying instruments we use daily have evolved, more and more, to emulate how humans perceive our surroundings.

There are 22 sensors in the head of the AEON: inertial, cameras, and more. While these are focused on situational awareness, navigation, and operational references for industrial settings, I asked Robert about potential field uses. He said that for instance, GNSS could also be leveraged for outdoor sites. For that matter, the AEON could serve as a platform for many more sensors moving forward.

And (I really like this), it can change its own batteries as needed.

Humanoid Survey Assistants?

Hexagon has in no way implied that this bot is, in its present incarnation, destined for surveying and geomatics applications. Presently, the focus is where the needs, and potential benefits are: industrial applications. But, look what people have done with robo dogs!

The AEON is continuously sensing its surroundings, precisely, and in 3D. While not intended for reality capture in the sense of surveying and mapping (yet), there could conceivably be a way to leverage what it is capturing for many other applications. However, it might make for a very expensive reality capture system. Then, what else could a humanoid add to field operations? Potentially plenty, though in the early days of any automation for surveying (and just about any other application), first reactions tend to focus on what something can’t do.

About 15 years ago, when affordable drones first started to appear for mapping, there was the obvious “It can’t find a property corner, or dig up a monument”, and even some “Shoot em’ down!” Sure, a drone still can’t find property corner (but what it captures can sometimes help in searches), but did that stop them from being rapidly adopted? Within a few years, the din of gripes about things drones couldn’t do got drowned about the praises over the reality of what they can do. Now, drones are essential kit for many surveying firms. For those who can remember the early days of laser EDMs, there were always folks who insisted on also pulling a chain/tape, because they couldn’t trust the laser. Its natural to be wary of things until they are proven. Sometimes though, skepticism, or dismissing things that don’t seem to fit traditional surveying molds, can mean missed opportunities… remember GIS?

What could a humanoid on your crew bring to the table? Safety is an obvious aspect. But also, considering the sensory capabilities of it, leveraging AI feature recognition and analysis, it could do rapid evaluations of a sites for capture tasks. Then, depending on the site conditions and complexity, a humanoid could potentially perform much of the topo and reality capture. Of course, there would be many qualifiers. But for some repetitive tasks, like mass stakeout, a humanoid could deliver tremendous productivity gains.

Until I saw the AEON, and found out more details, I had envisioned humanoids for surveying and geomatics as being on distant horizon. Now, I’m more optimistic.

I view these developments, overall, as a good thing. I don’t pine for some idealized past but would surely pine for future opportunity missed.

Be the first to comment