geoBIM Assessment Reveals How to Optimize Earthworks and Reuse Material for Structural Support. How Mott MacDonald Reduced Material Moved from a Massive Rail Site, Sharply Reducing Carbon Usage

“The construction team can optimize the mass haul movements during the permanent works through targeting the excavation of particular areas of the cutting to obtain fill that meets the class requirements for whatever is getting constructed at the time.” – Peter Fair, Geotechnical Data and 3D Ground Modeling Specialist, Mott MacDonald

Significant Earthworks from a Massive Project

Major infrastructre development projects are often significant sources of carbon emissions, and COP26, the 2021 United Nations’ climate change conference, put a renewed focus on how engineers can help mitigate climate change. Mott MacDonald is developing the 90-kilometer northern section of the High Speed 2 (HS2) Phase 1 rail project and earmarked over 21 million cubic meters of material—equivalent to 8,400 Olympic swimming pools—for removal. Despite the enormous number of energy-intensive earthworks needed, the HS2 project has pledged to reduce carbon emissions by at least 50% during construction and operations. Mott MacDonald needed to determine how to significantly lessen carbon emissions during material removal.

Seeking Better Coordination of Material Movement

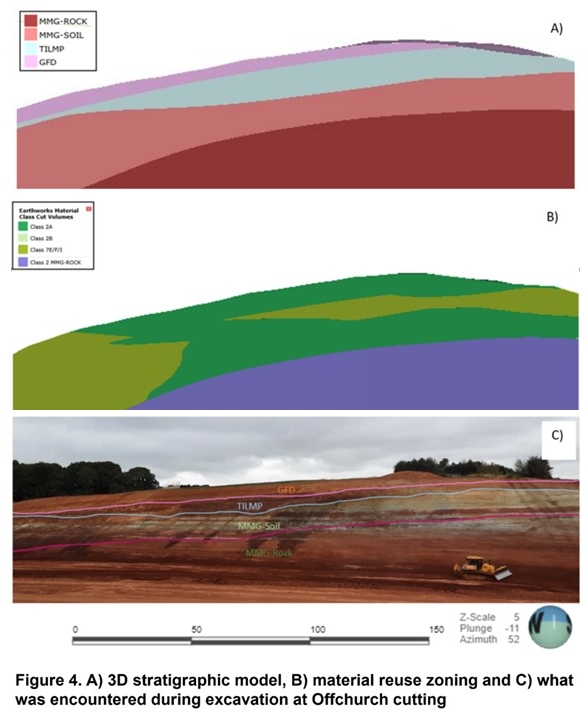

Engineers determined that they could lower emissions by identifying mass haul efficiencies, minimizing the unnecessary transportation, treatment, and disposal of site material. Reusing the removed material could reduce the need for sending it to landfills, as well as reduce the amount of material brought to the site. However, conventional methods for assessing potential reuse of material do not always give a clear, 3D indication of the distribution of materials across the work site. The team also faced challenges coordinating the work of multidiscipline teams working across many offices, companies, and time zones, as well as multiple phases of earthworks undertaken within 45 separate contracts. Therefore, Mott MacDonald needed a way to improve both assessment and coordination.

Optimizing the Process with Improved Assessment

Mott MacDonald determined that they could accurately determine how to minimize material removal by leveraging OpenRoads and ProjectWise with Seequent Central and Leapfrog from Seequent, The Bentley Subsurface Company. The team developed a collaborative geoBIM assessment technique that allowed them to undertake 3D spatial assessments of ground investigation data within the proposed earthworks excavation areas. All teams, contractors, and stakeholders could view and share the intuitive visualizations, which helped inform their work. Mott MacDonald then modeled specific geometric earthwork profiles, helping them to optimize mass haul movements during construction and gain critical insights into reusing material across the project.

Preventing Carbon-intensive Hauling

The organization’s geoBIM assessment identified both the amount of material targeted to be removed and its precise location, allowing construction teams to optimize mass haul movements and reuse fill for project elements being developed at any given time. As a result, Mott MacDonald maximized material recycling while minimizing material sent to the landfill, importing additional fill, and the distance material is transported. All these factors are projected to sharply reduce the amount of carbon emissions generated from excavation and transportation, as well as provide a foundation for similar carbon reductions on other projects with earthworks.

Software used by Mott MacDonald for this geoBIM assessment included: Keynetix, Leapfrog, OpenRoads, ProjectWise, Seequent Central

Outcome/Facts:

- The massive High Speed 2 rail project in the U.K. has pledged to lower carbon emissions from construction and operations by 50%.

- Mott MacDonald turned to digital modeling and geological assessment to determine how to significantly lessen carbon emissions produced during material removal.

- By maximizing material recycling while minimizing material sent to the landfill and the distance material is transported, Mott MacDonald provided a foundation for significant carbon savings during future earthworks.

Be the first to comment