2024 Going Digital Awards Finalists for Innovation in Infrastructure

Finalists for the 2024 awards have been announced, and it’s time to highlight a few of our “hot picks”…

The Year in Infrastructure – Going Digital Awards selects finalists from global nominations for categories representing innovation in key aspects of the digitalization of AEC and infrastructure. This is one of, if not the, premier annual global infrastructure awards program. Categories focus on infrastructure industry sectors, which include transportation, energy, facilities, and more, in any phase of infrastructure lifecycles—planning, design, construction, and operations.

While we highlight some finalist projects, we find intriguing, it should be noted that the finalists will present their projects before an expert panel of jurors, and attendees of the Year in Infrastructure event (YII). Winners will be chosen by this panel at the event. YII is hosted by Bentley Systems, and this year will be held in Vancouver Canada, 8-9 October 2024. YII has been held in either London or Singapore for many years. This will be the first YII held in Vancouver.

Winners and finalists will be honored at the gala Going Digital Awards dinner and featured in the annual Infrastructure Yearbook.

You can check out the finalists for each of the 12 categories, but we’d like to highlight a selection of finalists from several of the categories that substantially include geomatics elements—our “hot picks”, so to speak. It goes without saying that all finalist entries are award-worthy, however, we like to make our picks based on trends in the respective industry sectors that seek to address points-of-pain that would otherwise have stifled increased productivity.

It is great again to see the relatively new category of Surveying and Monitoring (in its third year), highlighting the vital role of surveying and geomatics.

While the projects themselves are impressive, often from sheer scale and scope, what these awards focus on is the benefits realized by the digitalization of various aspects of the projects, through the use of modeling, visualization, analysis, project management, and collaboration:

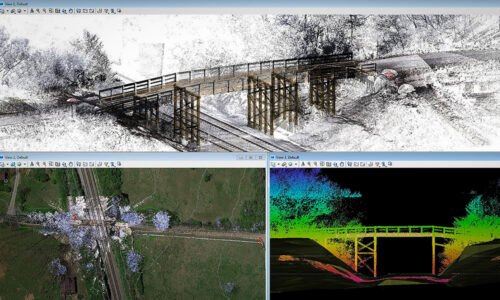

Bridges and Tunnels

Bridges and Tunnels

The application of digital twin technologies for the rehab of as many as 1,000 bridges speaks of a growing trend in the industry trend of tapping digital twin technologies for surveying and reality capture data. QK4 Inc. chose the iTwin path for at least 700 bridges of the Bridging Kentucky initiative by the namesake state in the U.S.

We’ve been keeping an eye on various bridge rehab initiatives in different states (many funded by the Infrastructure Bill of a few years ago) and have seen a few that are going a digital twin path. For this initiative, QK4 is estimating substantial savings in both the field time for surveying and overall survey-related costs—as much as $3M in savings from a total estimated $7M overall cost for Bridging Kentucky.

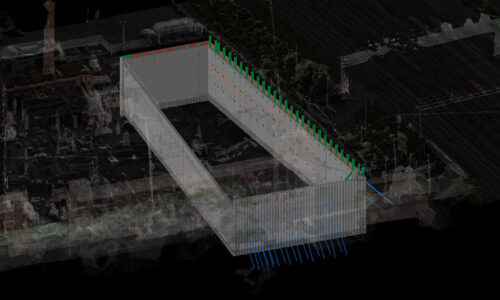

Surveying and Monitoring

Surveying and Monitoring

A construction project in Toronto Canada is doing digital twinning—true digital twinning. What we mean by “true” is that the digital twin will not just be a 3D model but will incorporate data from IoT sensors. All too often, during the early “buzz” days of the term digital twin, we would see, for instance, outfits that might do a drone flight or terrestrial close-range photogrammetry, build a 3D mesh model, and call that a digital twin. True digital twins are dynamic, both spatially and in data integration. For monitoring, one or the other does not provide a complete representation of the subject structures/environments.

Monir Precision Monitoring has piloted the integration of its sensor-based monitoring systems with iTwin IoT. The impetus is to increase efficiency in the construction of a condominium project to reduce disruption of a nearby rail line. Monir is estimating 40% in increased efficiencies. Not to mention that a high-fidelity digital twin can be utilized long-term (provided it is updated) for operations, simulation, maintenance programs, and any subsequent design engineering. It is heartening to finally see more of this.

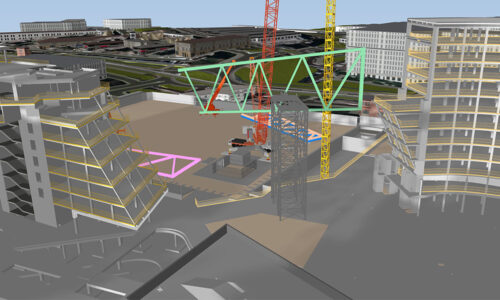

Construction

Construction

The three finalists are each applying 4D construction tools and techniques to reduce timelines, and costs, detect clashes, and reduce rework: the key benefits of digital construction. One that stood out was the construction of a large steel sky bridge connecting buildings of the new ENI (energy firm) headquarters in Milan Italy.

Contractor Webuild S.P.A. is utilizing a collaborative, virtual construction environment. Benefits realized include a 90% reduction in rework (the chief point of pain in legacy construction) and shortening the 85-day estimated construction schedule to four days.

Enterprise Engineering

Enterprise Engineering

Collaborative data environments for infrastructure projects are not new, however, many of the simple web-based tools suffer from scalability challenges. Amey, a life-cycle engineering firm chose a more robust project and data-sharing solution, having to serve over 1,500 collaborative users across 40 organizations. Working within this environment enabled the broader team to develop over 30 ISO-standard automated workflows.

This improved collaborative approach is being applied to the £1B Core Valley Lines rail improvement project for the Cardiff region of Wales. While Amey had previously used simple web-based tools, they realized (as we hope many more construction projects would) that you sometimes “need a bigger boat”.

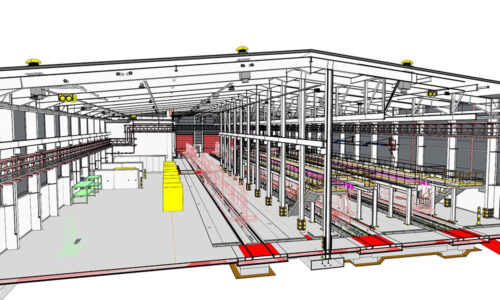

Facilities, Campuses, and Cities

Facilities, Campuses, and Cities

Garbage treatment facilities might not seem very exciting, however, what we like about this entry is that it is a splendid example of a jump from the legacy 2D design and construction world into full 3D, and a lot more. China ENFI Engineering went all-in, adopting not only a 3D environment but a dozen engineering software packages that can work together in this digital environment.

This enabled more 3D simulations which, among other benefits, eliminated the need for four construction cranes. Overall, ENFI estimates improvements across multiple processes of as much as 130%, shaving 50 days off the construction schedule and saving 14M CNY (about $2M USD).

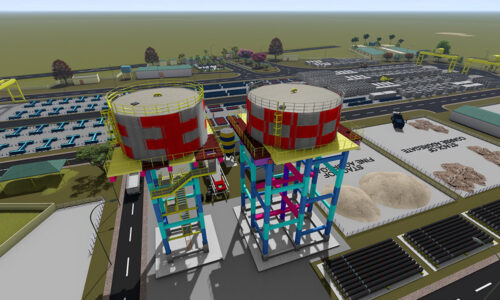

Process & Power Generation

Process & Power Generation

The design and building of the first hydrogen metallurgy (demonstration) facility (in Hebei China) is a very complex project on many levels. There are many engineering disciplines involved, a lot of piping and conveyances in a tight space, and many tolerances far greater than legacy smelting facilities. MCC Capital Engineering & Research Inc. went full BIM on this one.

Identifying potential clashes was essential, and through virtual planning and simulations, hundreds were identified, and the construction schedule was reduced by a third. A dozen engineering software packages were applied across multiple disciplines, and this was all managed within a digital collaborative environment.

Rail & Transit

Rail & Transit

The electrification of the Midland Main Line in the UK encompassed over 400 Km of track, with thousands of overhead structures. The potential for rework was great, so SPL Powerlines went the full digital twin and project management path. Starting to see a pattern in all categories? Yes, going digital represents (I would argue) the biggest leap in realizing engineering, construction, and operational gains of any era.

The team consists of 20+ organizations, all able to access the latest design information from the collaborative environment. SPL notes that in the first month of new design submissions after adopting this new approach, the success rate rose by 25%.

Roads and Highways

Roads and Highways

Each of the finalists has adopted digital twins and collaborative project and data management environments. The NLEX-SLEX Connector Road Project in Manila Philippines leveraged a mixed reality environment to help thread this road corridor through one of the most densely populated urban areas in the world.

The Department of Public Works and Highways (DPWH) can plan in this virtual environment for complex right-of-way situations, stage construction equipment, and materials. DOWH estimates boosts in overall productivity of 15% and 40% in equipment logistics. Anyone who works in construction knows that idle equipment means lost time and money.

Structural Engineering

Structural Engineering

Each finalist excelled in the use of advanced structural analysis and design software. For certain processes, what would have taken hours or days can often be done now with a few button clicks. However, you need to make sure those buttons are doing things correctly, and within design parameters. To this end, our pick took their stringent criteria and merged their processes into the processes existing advanced software.

Hyundai Engineering of Seoul Soth Korea went and extra step, using an API for a popular structural software to integrate with their advanced processes. Hyundai estimates that this updated process has reduced structural analysis time by 70%, and reduced design errors by 50%.

Subsurface Modeling & Engineering

Subsurface Modeling & Engineering

Good geotechnical data is an essential prerequisite to the design process for heavy civil projects. Overlook or miss some crucial sail instability data, and you could set a highway project back and cost millions in redesign, and mitigation. For a highway project, nearly 3,000 Km long, the stakes were quite high.

The Trans Sumatra toll road traverses an area of Indonesia with a diverse and challenging terrain and weather patterns. This compounds soil conditions. PT Hutama Kayra (Persero) created a digital twin of a section of the corridor and applied two advanced geotechnical modeling software suites to analysis and design. For the 40 Km section of the main project, they estimate increased productivity of 15%, and identification of potential losses (were soil stabilization not addressed) of over $100M USD.

Transmission and Distribution

Transmission and Distribution

The Ohio Falls River crossing transmission towers are huge and iconic, but over 100 years old. However, a comprehensive modeling, inspection, and maintenance program could extend their life for many years/decades. A replacement would cost $80M USD or more.

A program of drone flights, capturing 250 GB of images was used to process a 3D mesh model for virtual inspection. The data is added to the digital twin and analyzed in a power line management software. Exo Inc. (asset management for power systems) was tapped to implement key elements of this program. They estimate that this advanced set of processes may have helped the utility avoid 10 additional years for permitting.

Water and Wastewater

Water and Wastewater

Among the challenges facing the Uttar Pradesh Tube well project in India was hydraulic and structural modeling. The project will provide drinking water to over 1.7M households and 6.8M people. The design includes over 3,000 overhead tanks.

L&T Construction used both structural and hydraulic modeling software to evaluate over 600 design alternatives. It is estimated that this splendid example of “proper prior planning” may have saved as much as 90% of construction time.

The finalists and nominees are all outstanding. Read more about all finalists here.

Note: the YII 2022 Going Digital Awards nominees, finalists, and winning projects all feature the use of one or more Bentley Systems software packages (the host of the awards program).

Bridges and Tunnels

Bridges and Tunnels Surveying and Monitoring

Surveying and Monitoring Construction

Construction Enterprise Engineering

Enterprise Engineering Facilities, Campuses, and Cities

Facilities, Campuses, and Cities Process & Power Generation

Process & Power Generation Rail & Transit

Rail & Transit Roads and Highways

Roads and Highways Structural Engineering

Structural Engineering Subsurface Modeling & Engineering

Subsurface Modeling & Engineering Transmission and Distribution

Transmission and Distribution Water and Wastewater

Water and Wastewater