Leveraging Bentley Systems Digital Twin and IoT Solutions, a Canadian Monitoring Firm Earns an International Infrastructure Award.

A next step-up in structural and site monitoring had been a long-time goal for Ontario, Canada-based Monir Precision Monitoring Inc. However, the team was looking beyond just updated monitoring sensors and systems. They sought to present their clients with a more holistic, automated approach in the form of an evergreen digital twin to enable rapid decision-making.

Much Needed Change

Structural monitoring has integrated digital sensors, or analog sensors that could be pathed through digital channels for decades. However, the state of monitoring sensors and systems has not While there are still some legacy sensors where readings are manually read, or retrieved periodically, most are at least bridged with gateway devices. Analog or digital sensors of almost any kind can, for instance, feed serial data into popular data hubs, which can feed into data aggregation systems or servers. But even with such digital conveyances, clients, project managers, and stakeholders would still need to navigate the context of readings and how they fit into the project design, progress of construction, or operations of the subject infrastructure.

“The client sees readings, and they go, ‘OK, it’s moved’, but where is it, where are the targets?,” said Samantha Ford, president of Monir. “You have to try and find the 2D plan somewhere. For Monir, it’s all about bringing crucial information into one location, where they can have the full context of the job site. Everything moves quickly, and some owners or site representatives must make multimillion-dollar decisions in a 15-minute window.”

The world of infrastructure now moves at a faster pace, it has to. The global demand for new, updated, smarter, and greener infrastructure, plus tighter margins in construction, makes further automation imperative. Can firms keep up with demand and stay competitive with legacy tools and solutions? Monir saw an opportunity to step up and move forward.

The Transformative Project

The 31 Parliament Project in Toronto was Monir’s candidate for not only updating to more modernized sensors but also aggregating and presenting the data in a detailed 3D digital twin of the site. The challenges presented in constructing 31 Parliament meant that a broad range of new or updated sensors could be tested together. 31 Parliament is a 41-story mixed-use development, that includes 428 residential units, and 4 underground parking levels. Being in the historic distillery district of Toronto, in the Don River floodplain, adjacent to a busy rail corridor and other construction sites, the stakes for monitoring were high.

Monir deployed accelerometers, shape array sensors (SSA), 200+ monitoring prisms (for the shoring wall abutting the railway). Bringing all of that real-time data smartly together was the next step.

Monir had also been exploring software suites, turning to Bentley Systems for key tools for developing and operating digital twins for monitoring. “We were familiar with their design software foundation, and we were pleased to see newer elements than their previous offerings, and expansion into more of the infrastructure life cycle; so, it’s exciting. It’s definitely a fresh new space for us to work in with them.” Solutions from Bentley System that were tapped by Monir, and their sister company Isherwood Geostructural Engineers on the project included: ITwin Capture, iTwin IoT, iTwin Experience, OpenGround (geotechnical) , and MicroStation (CAD).

Updating Sensors

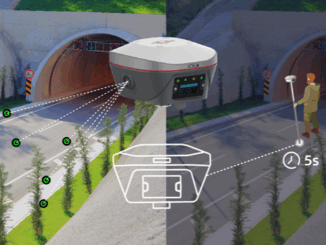

Monir has also been upgrading to newer sensors: IoT sensors that are, more and more, becoming “plug-and-play”. “We want to be able to take an instrument off the shelf, plug it into the system, add the calibration files and serial numbers, and have everything cataloged everything being cataloged very quickly,” said Ford. “This speeds up our ability to support our clients, so we didn’t have to have a week and a half in the back-room programming all of these job sites that were custom builds every time.

By adding many new sensors from Sensemetrics we were able to very quickly decide what we needed to deploy to a site, put it together, and test it. And without having to worry if we put a comma in the wrong spot that’s going to break the program? That was the way it often was in the past.”

One driving force for Monir to modernize was to meet customer needs quickly, in the design and deployment of site monitoring systems. The other driver was to streamline ongoing operations and provide real-time access for clients and site managers.

Ford stated that the reality of monitoring deployments is that whatever system they use to operate, it needs to be hardware agnostic. This was not an issue with data aggregation and operations in Bentely’s iTwin IoT environment. For example, data from a Leica Robotic Total Station (with observation rounds controlled in its companion software) shooting deflection prisms set on key structures, was seamlessly integrated. “And we wanted more flexibility with our software and programming choices,” said Ford. “Because we really want it to be customized to the client’s needs, not just ‘here’s the deliverable, take it or leave it’. These solutions have worked out great for us, so we’re piloting other projects now.”

Evergreen Digital Twins

Arguably, any 3D model of a site or infrastructure could be labeled as a “digital twin”. However, the true power of digital twinning comes in not just reflecting a snapshot of the physical geometry, but in currency and integrated data—especially real-time data. Then it becomes an evergreen digital twin.

Monir would continually update the site condition with drones and other instruments, to show the progress on construction. Sensors were added with iTwin IoT. With a click, the monitoring time series for each sensor and groups of sensors where applicable, can be viewed. Sensor nodes in the iTwin can be set to automatically show color codes for different condition thresholds, warnings, and automated alarms. To enable these features for their team, the site managers, and clients, Monir integrated the digital twin, and IoT data into Bentley’s iTwin Experience; an immersive environment that can be viewed internally, and externally via a secure web interface, with all of the monitoring data linked. There is also a slider bar to show site changes over time.

For the 31 Parliament project, Monir earned a Founders Honors Award for Surveying and Monitoring, and the Year in Infrastructure (YII 2024). The takeaway from this project for clients of their monitoring services, as Ford puts it: “If the client can’t come to the site, we bring the site to the client”.

Be the first to comment